Sustainable Material Options

At AL NAFAY’ Commercial Development Centers, our staff stays up to date in the latest material developments.

As your trusted advisor, we continually evaluate new resins, colorants and additives, assessing the impact

that these materials can have on the environmental impact of your package.

By conducting independent material performance analysis, AL NAFAY can

provide guidance on product interaction and shelf life, recycling guidelines,

potential light weighting options and the impact of PCR usage.

Post Consumer Recycled (PCR)

AL NAFAY' total PCR usage across our portfolio ranges from 5 - 10%. We use anywhere from 10 - 100% PCR in our bottles, depending on customer specific packaging specifications.

PET

HDPE

-

AL NAFAY has multiple HDPE PCR suppliers, including one with FDA food grade PCR.

-

AL NAFAY can run HDPE PCR in both mono-layer & multi-layer applications.

-

With HDPE bottles, AL NAFAY has the ability to sandwich PCR in the middle layer of a tri-layer package. This way, the product in the bottle is only coming in to contact with the virgin material of the inner layer. Additionally, the process allows for a pristine outer layer for decoration and optimum shelf-appeal.

Custom Color Sorted PCR Savings

-

Colorant cost per pound is one of the most expensive components in the plastic packaging of a product. Recycling the colorant, as well as the plastic, however; saves money by reducing the amount of new colorant that must be bought. Overall, this reduces the cost per pound of PCR.

-

In most cases, colorant savings should be proportional to the amount of PCR used in the package. For example, if 25% colored PCR is used in a plastic bottle, the expected colorant savings would be 25%.

Bio-Resin

As the demand for sustainable packaging rises, so do the number of alternative resin options. Our Materials & Metrology team and Engineers are continuously investigating and testing new resin alternatives. From Post Consumer Recycled (PCR) to Bio Resin, AL NAFAY has the right solution to fit both your needs and budget.

With the rise in concern for sustainable packaging solutions, there is growing interest in plant-based bio resin. Traditional PET & PE resins are petrochemical based, whereas the bio-based alternative is produced with 30% of the material derived from sugarcane for PET and 98% for HDPE. The traditional petrochemical based resins and sugarcane alternatives have fully identical properties, processes the same and can be incorporated into the existing production lines.

AL NAFAY sources both PET & PE bio resin from multiple suppliers.

As the demand for sustainable packaging rises, so do the number of alternative resin options. Our Materials & Metrology team and Engineers are continuously investigating and testing new resin alternatives. From Post Consumer Recycled (PCR) to Bio Resin, AL NAFAY has the right solution to fit both your needs and budget.

With the rise in concern for sustainable packaging solutions, there is growing interest in plant-based bio resin. Traditional PET & PE resins are petrochemical based, whereas the bio-based alternative is produced with 30% of the material derived from sugarcane for PET and 98% for HDPE. The traditional petrochemical based resins and sugarcane alternatives have fully identical properties, processes the same and can be incorporated into the existing production lines.

AL NAFAY sources both PET & PE bio resin from multiple suppliers.

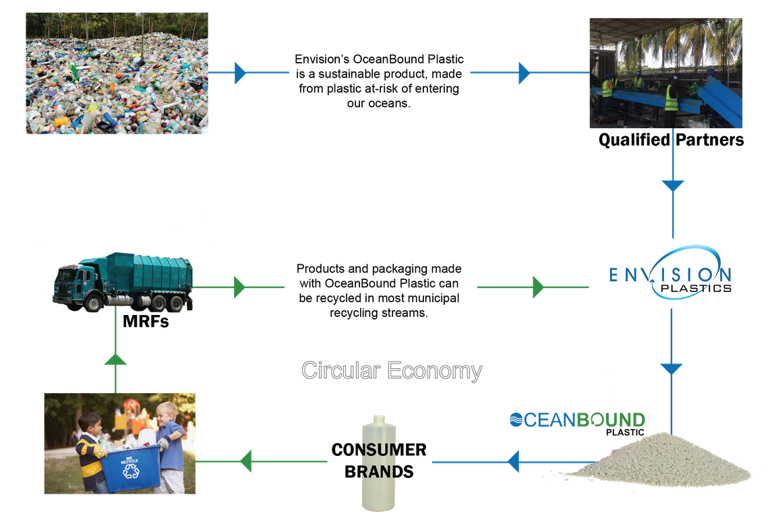

Beach Plastic (OceanBound) HDPE

Plastic obtained from Qualified Partners and verified as originating in the At-Risk Zone meets Envision’s criteria as OceanBound Plastic source material. Envision has combined supply chain experience with technical expertise and patented processes to transform plastic at-risk of polluting our oceans into a reliable resin, OceanBound Plastic.